|

Ruian Huabo Plastic Packaging Machinery Co., ltd.

|

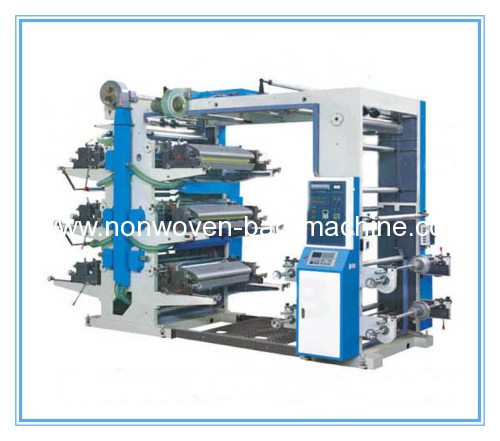

YT Series Six Color Flexo Printing Machine

| Price: | 5000.0~30000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag

Application:

Introduce sensitization resin as flexible printing plate, suitable for printing such packing materials as polyethylene, polypropylene bag, cellophane and roll paper, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Performance and Features:

1. Easy operation, flexible starting, accurate color register.

2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off.

3. Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4. The printing ink is spread by the anilox cylinder with even ink color.

5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

6. 360°continuous and adjustable longitudinal register device.

7. The frequency control of motor speed adapts to different printing speeds.

8. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

9. Magnetic powder brake for unwinding tension control. magnetic powder clutch for rewinding tension control.

1. Easy operation, flexible starting, accurate color register.

2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off.

3. Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4. The printing ink is spread by the anilox cylinder with even ink color.

5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

6. 360°continuous and adjustable longitudinal register device.

7. The frequency control of motor speed adapts to different printing speeds.

8. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

9. Magnetic powder brake for unwinding tension control. magnetic powder clutch for rewinding tension control.

Application:

Introduce sensitization resin as flexible printing plate, suitable for printing such packing materials as polyethylene, polypropylene bag, cellophane and roll paper, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Introduce sensitization resin as flexible printing plate, suitable for printing such packing materials as polyethylene, polypropylene bag, cellophane and roll paper, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Performance and Features:

1. Easy operation, flexible starting, accurate color register.

2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off.

3. Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4. The printing ink is spread by the anilox cylinder with even ink color.

5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

6. 360°continuous and adjustable longitudinal register device.

7. The frequency control of motor speed adapts to different printing speeds.

8. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

9. Magnetic powder brake for unwinding tension control. magnetic powder clutch for rewinding tension control.

1. Easy operation, flexible starting, accurate color register.

2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off.

3. Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4. The printing ink is spread by the anilox cylinder with even ink color.

5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

6. 360°continuous and adjustable longitudinal register device.

7. The frequency control of motor speed adapts to different printing speeds.

8. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

9. Magnetic powder brake for unwinding tension control. magnetic powder clutch for rewinding tension control.

Technical Data:

Type | YT-6600 | YT-6800 | AYT-61000 |

Max. Effective Printing Width | 560mm | 760mm | 960mm |

Max. Web Width | 600mm | 800mm | 1000mm |

Max. Printing Speed | 50m/min | 50m/min | 50m/min |

Max. Mechanical Speed | 60 m/min | 60 m/min | 60 m/min |

Max. Diameter of Roll Material | ф450mm | ф450mm | ф450mm |

Internal Diameter of Roll Core | ф76mm | ф76mm | ф76mm |

Rang of Repeat Printing Length | 191-914mm | 191-914mm | 191-914mm |

Accuracy of Registration | ±0.5mm | ±0.5mm | ±0.5mm |

Plate Thickness(Both side adhesive included) | 2.38mm | 2.38mm | 2.38mm |

Heating Power | 9Kw | 13.5Kw | 18Kw |

Total Power | 15Kw | 19.5Kw | 24Kw |

Weight of Machine | 3500kg | 4200kg | 5000kg |

Overall Dimension | L4300×W1700×H2950mm | L4300×W1900×H2950mm | L4300×W2100×H2950mm |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Flexo Printing Machine

Label Flexo Printing Machine

Color Printing Machine

Four Color Printing Machine

Flexo Printing

Label Flexo Printing Machinery

More>>

.jpg)

.jpg)

.jpg)